Client Challenge

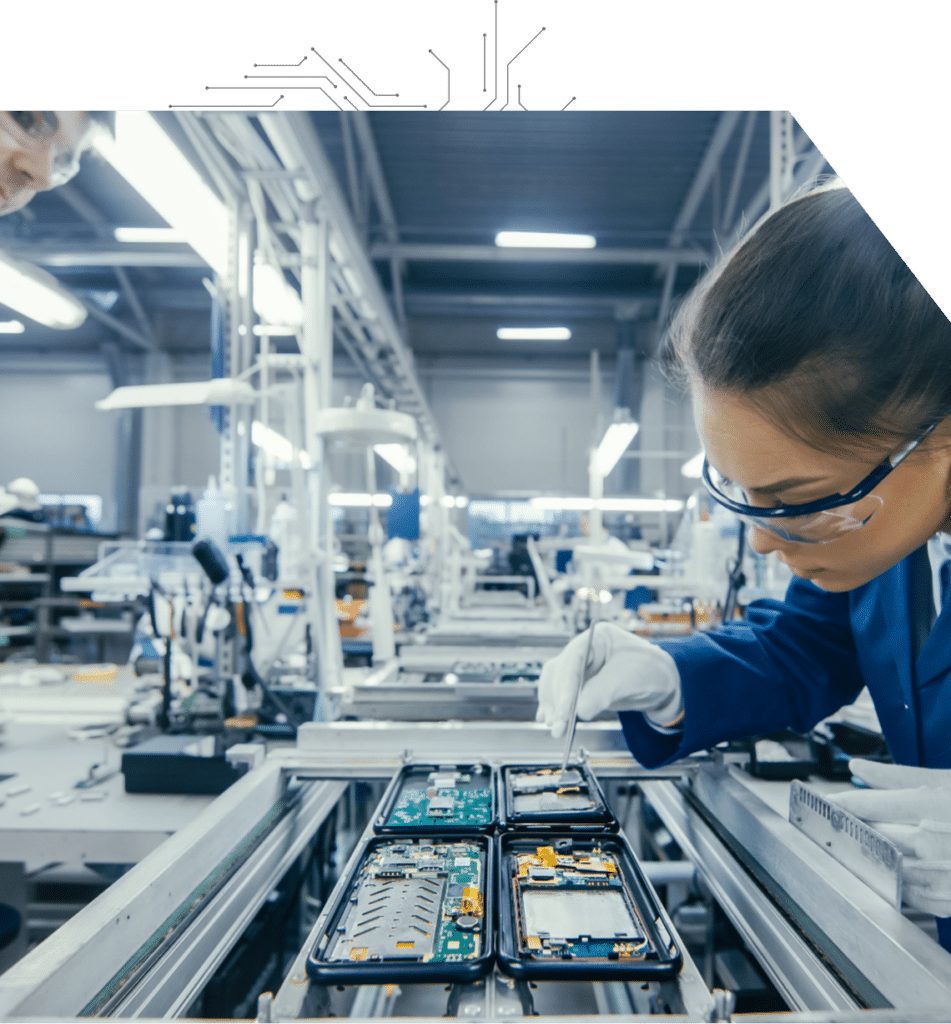

A leading electronics manufacturer engaged Assembly Solutions for a new board assembly project. Unaware of any existing manufacturing concerns, the client did not raise any specific issues—but they had faced quality challenges with a previous supplier on similar assemblies.

Solution

Assembly Solutions proactively conducted a risk analysis as part of their standard onboarding process. During the review, our engineering team identified a potential failure point in the manufacturing and flagged it as a high-priority risk.

Assembly Solutions implemented targeted improvements, including:

- Process changes to eliminate the risk

- Enhanced inspection checkpoints

These changes were made before the customer had the opportunity to identify concern from the previous supplier’s manufacturing issues.

Results

After Assembly Solutions implemented the solution:

- The identified risk was fully mitigated before production began

- The customer later communicated the same issue had caused problems with their former supplier, but Assembly Solutions already identified the risk

- Our proactive measures eliminated costly delays and boosted the client’s confidence in our process